Amprius 500 Wh/kg Battery Tech Could Revolutionize EV Market

By Edward A. Sanchez — March 29, 2023

Most of the time, the research and development process is incremental and iterative, with evolutionary change characterizing the pace of progress rather than sudden quantum leaps. But those quantum leaps do sometimes happen, and the announcement from Fremont, Calif.-based Amprius Technologies, independently verified by a third-party lab, could be one of them.

As we’ve discussed numerous times on our blog and podcast, EV batteries have lagged the power density of liquid hydrocarbon fuels for a long time, and we’re likely decades away from volumetric power density parity, with gasoline packing 33.7 kWh of potential energy per gallon (8.76 kWh/liter) and diesel boasting an even more dense 40.7 kWh per gallon (10 kWh/liter). The obvious difference being that internal combustion consumes the liquid fuel in the process, whereas battery electrics only consume the stored energy, and leave the physical medium of the battery pack intact. Some would argue that makes the comparison an “apples and oranges” one, but I digress.

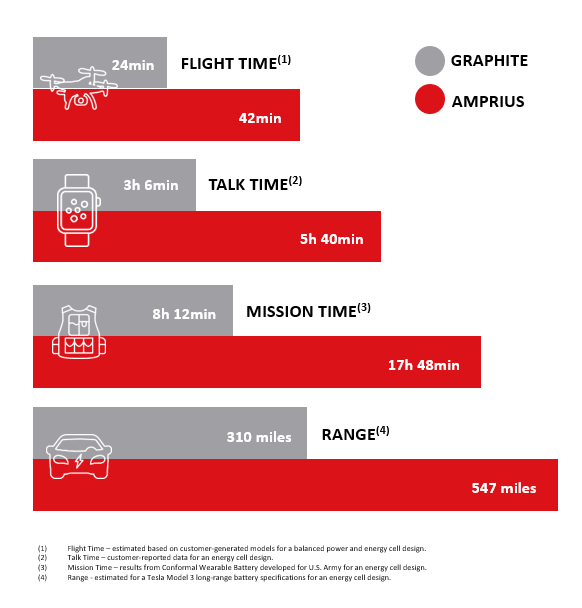

Until now, 250 Wh/kg was considered a competitive power density for EV batteries. But the latest announcement from Amprius could represent a quantum leap in EV battery pack power density, with a claimed power density of 500 Wh/kg, validated by third-party testing lab Mobile Power Solutions.

The EV game is all about efficiency and energy density, and it could be that Amprius’ latest endeavor massively aids that latter endeavor.

Lithium Iron Phosphate (LFP) with a two- to four-times lifecycle advantage over the commonly used NMC (Nickel Manganese Cobalt), is the reigning champ for longevity for commercialized battery chemistries for EVs, with a charge/discharge cycle life of 3,000+. The tradeoff is lower power density of LFP compared to NMC, resulting in bulkier and heavier packs relative to an equivalent-capacity NMC.

Chinese battery giant CATL, the world's leading supplier of LFP packs, recently announced start of production on its next-generation Qilin packs, offering up to 250 Wh/kg with NMC chemistry, and up to 160 Wh/kg with LFP, so the power density advantage of Amprius’ silicon nanowire technology is clear. Additional claimed advantages of the silicon nanowire design are dramatically reduced anode swelling, and the ability for denser application of lithium, a key factor in battery energy density.

In terms of durability and lifecycle, Amprius is claiming 90% capacity retention after 1,200 cycles in its eVTOL flight protocol testing for its 370 Wh/kg packs, which consists of 30- to 45-minute trips, 15 minutes of charging, and eight to 12 trips per day.

Amprius' primary applications to this point have been in the defense and aerospace industries, which have rigorous performance and durability requirements in their own right, but are very different use cases than automotive. The closest analog to automotive in which Amprius has applications is eVTOLs, in which its 15+ Ah, 380 Wh/kg batteries are available for immediate shipment. The company also offers applications for High-Altitude Pseudo Satellites (HAPS) and Unmanned Aerial Systems (Drones).

The other unknown (or unannounced) factor with Amprius' pack technology is cost – probably the biggest issue that OEMs and suppliers are trying to tackle with EVs currently. Cost generally comes down with scale, and on that front, Amprius has announced the selection of a site in Brighton, Colo., northeast of Denver, for its future 775,000 square foot production facility, targeted to be operational in 2025.

The EV startup market is rife with claims of “breakthroughs” and “revolutionary” technologies, as well as overly optimistic timelines and goals for production and commercial availability. Often, companies are reluctant to make their technologies available for third-party testing and validation, making their claims basically worthless. The fact that Amprius has existing relationships with the Department of Defense, and has had its performance claims independently validated, is an encouraging sign. While still likely several years away from production application in EVs, Amprius’ technology could be a major catalyst in the development of lower-cost, more efficient, and longer-range EVs.

(Images courtesy Amprius)

- Store - Podcast - Facebook - Google News - Twitter -